Technology

As a driving force in the development of specialised welding and coating systems for onshore and offshore projects, CRC Evans provides an extensive range of technology and equipment for a variety of project applications.

Cutting edge, customisable technology

CRC Evans has a proud history of innovation, utilising our depth of knowledge which has been gained over many years of successful delivery to overcome technical challenges that can arise during the fabrication, construction and installation operations. With our experience and expertise we are able to provide the right solutions at the right time.

Our fleet of specialist welding and coating equipment and advanced technologies supported by our expert global teams ensures that we can provide a broad range of services and bespoke solutions to meet our customers’ complex engineering requirements.

In-house design and manufacturing

CRC Evans is committed to bringing the latest innovations to our customers with a talented team of in-house design and manufacturing specialists driving the development of cutting-edge technologies such as artificial intelligence and analytics, assisted defect recognition (ADR) and data-driven digital solutions.

Our bespoke technologies, equipment and processes are engineered to allow high speed, repeatable, high quality results whilst our automated solutions are designed to reduce material consumption and wastage, helping to minimise environmental impact.

We are continually developing our portfolio through scheduled R&D programmes and a talented team of engineers, a commitment that help to ensure that customers have access to the most effective, technically advanced solutions available.

Our SmartLync advanced data-driven digital ecosystem is transforming pipeline construction with real-time data collection, reporting and seamless communication.

Mechanised welding offers a number of clear advantages over manual welding for high capacity, high accuracy welding scopes. It simplifies welders training, helping to reduce manpower demands in a supply constrained market and helping to increase welder productivity.

An increase in weld consistency across large scale projects helps to minimise welding repairs and reduce rework, helping to maximise production and efficiency.

Digital records through parameters recording supports quality assurance and QA/QC reporting for improved integrity management.

Our equipment

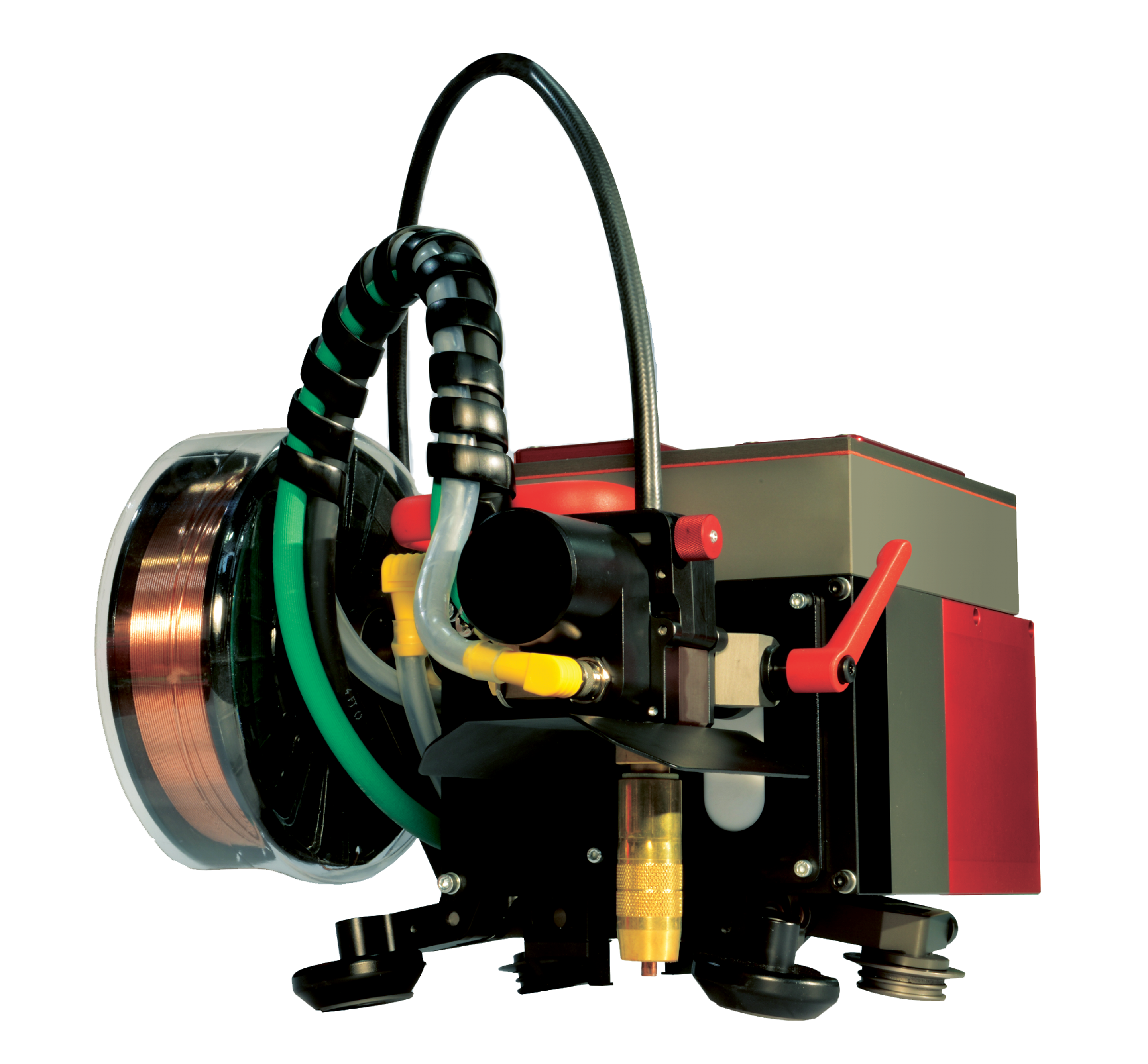

Single Torch External Welding System

The CRC Evans M500 Single Torch External Welding System delivers exceptional arc visibility, high-speed travel, and intuitive single-action installation. Onboard voltage and current sensing and adjustable head allows rapid head angle changes. The M-500 provides reliable and consistent weld quality enabling high production rates and helping to reduce operational time and cost.

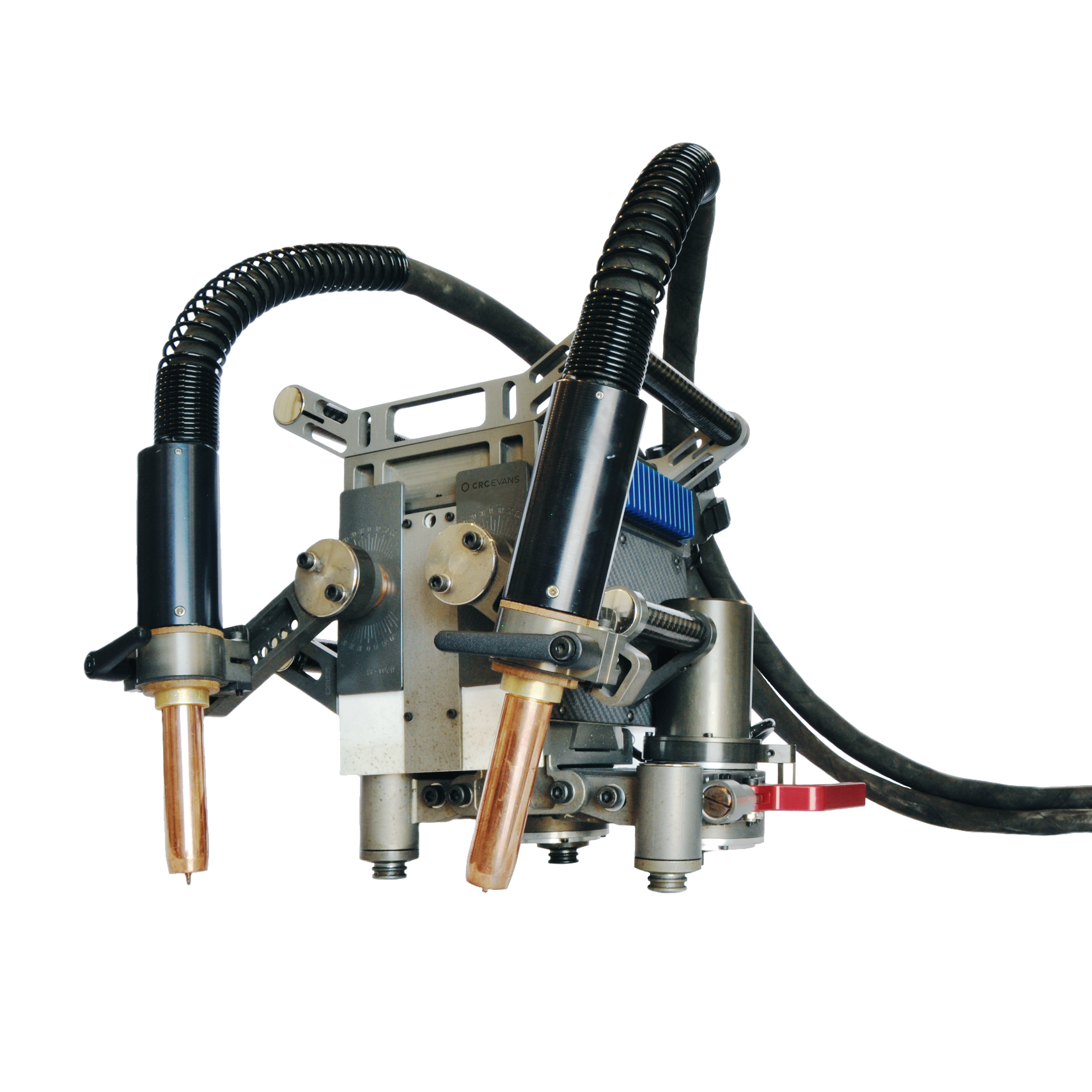

Computerised Welding Machine

The CRC Evans P625 external welder is a dual torch external welding system offers consistent welding parameter quality control, and provides users with 32 programmable welding passes per torch. In addition, this welding machine offers both horizontal and vertical tracking to maintain the center of the bevel and tip to work distance.

Laser Pipe End Measurement System

The CRC Evans Laser Pipe End Measurement System (SCIO) ensures accurate alignment where minimum high-low is requested, such as CRA or SCR pipelines without counter boring. Analysis of the measurement is can estimate high-low in a random pipe sequence, with optimisation of pipe alignment to improve project time and efficiency.

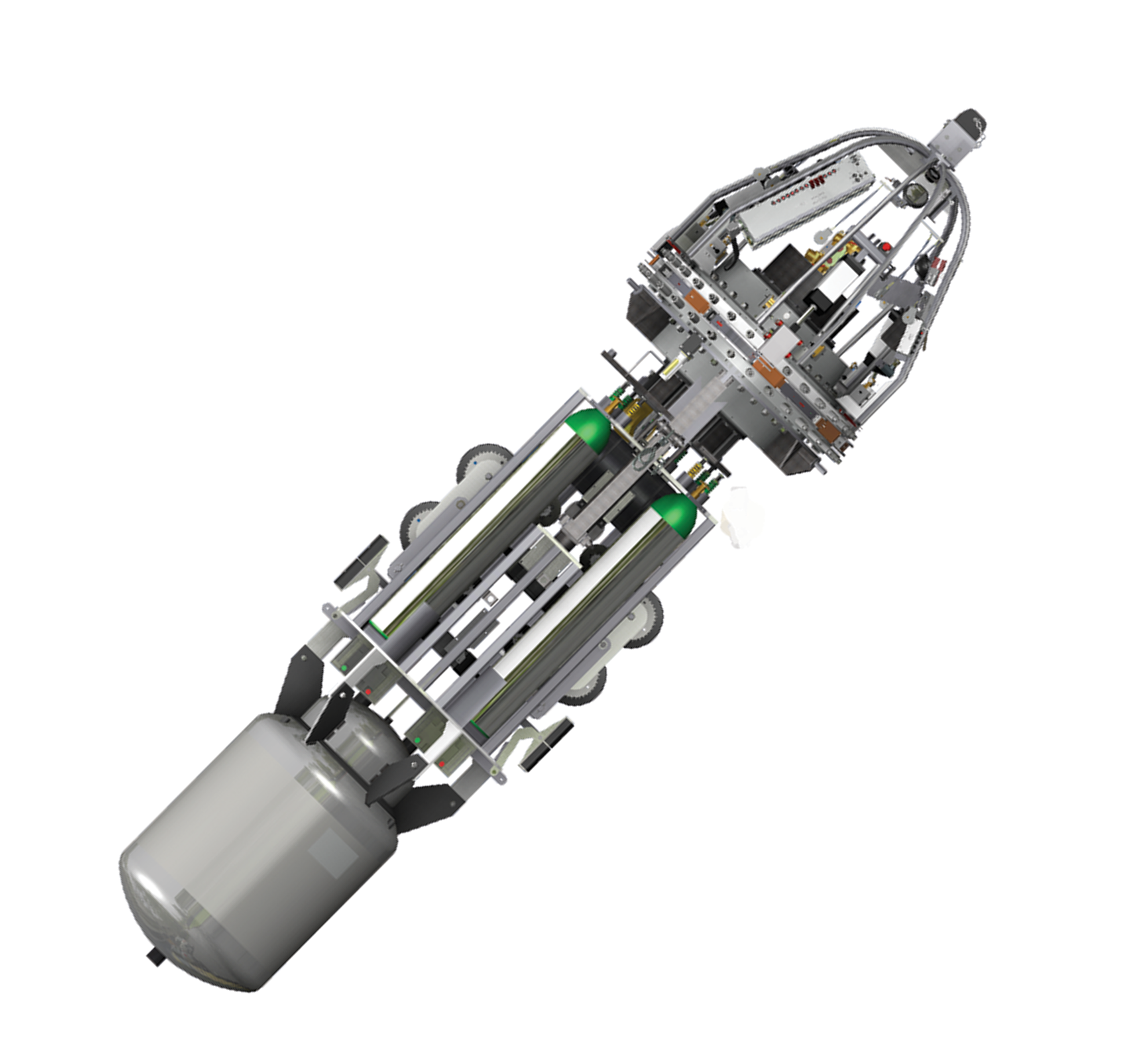

Internal Welding Machine

The CRC Evans Internal Welding Machine (IWM) is a combination internal clamp and automatic multi-head internal root pass welding system. Available in two variations – barge or offshore applications, or land or standard pipeline right of way. A self-contained low voltage electrical source provides power for the shielding gas, air control valves, ring drive and wire feed motors. The self-contained pneumatic system operates the travel motors, brakes, drive wheels, aligners, and front and rear clamping shoes.